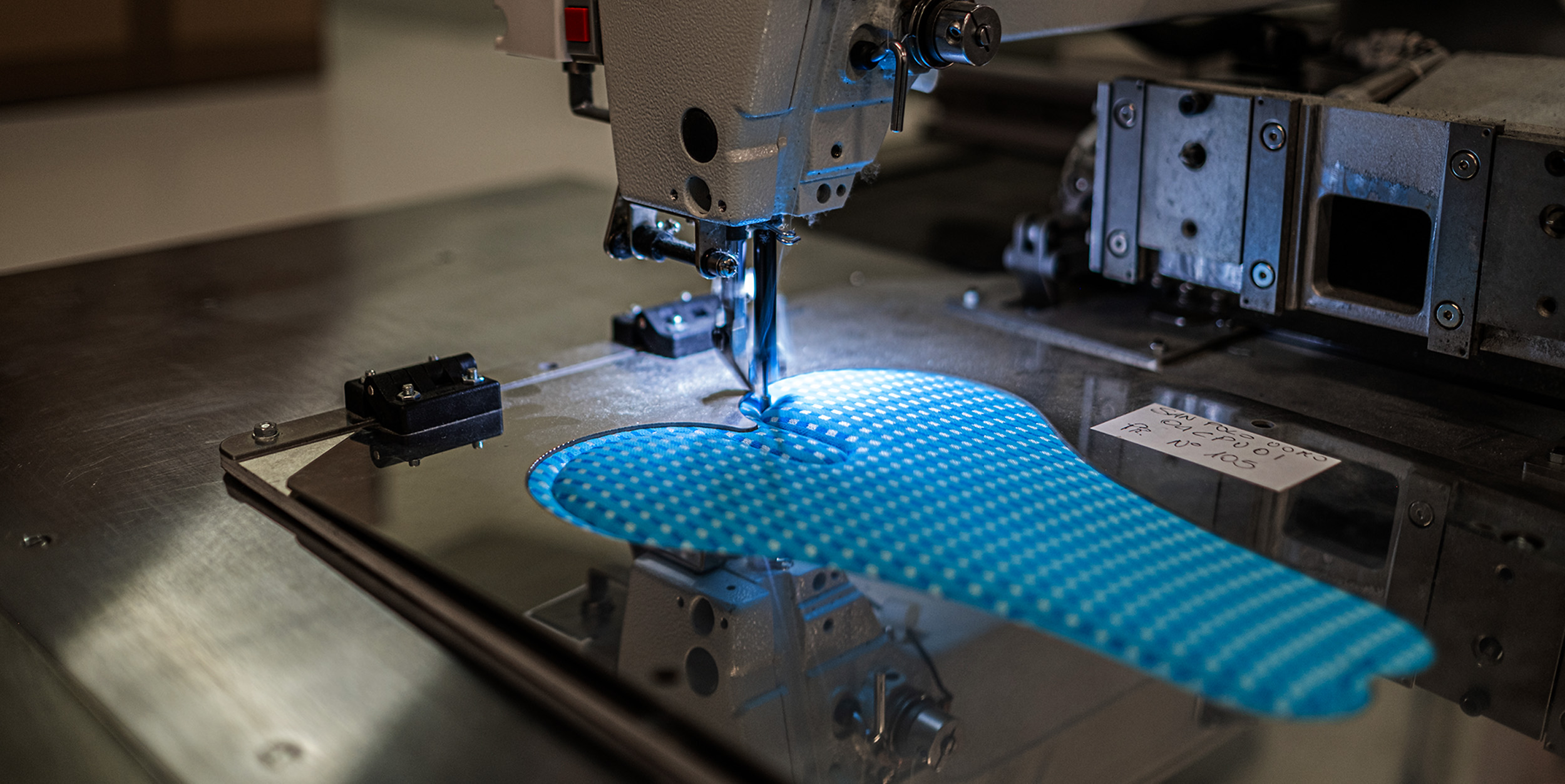

Thanks to our "shaped edges" technology, the various product ranges have a differentiated thickness which offers considerable support in the pressure areas, keeping the rest of the pad soft and elastic.

Cycling is a pleasure, but often it collides with aches and pains in the ischial area..

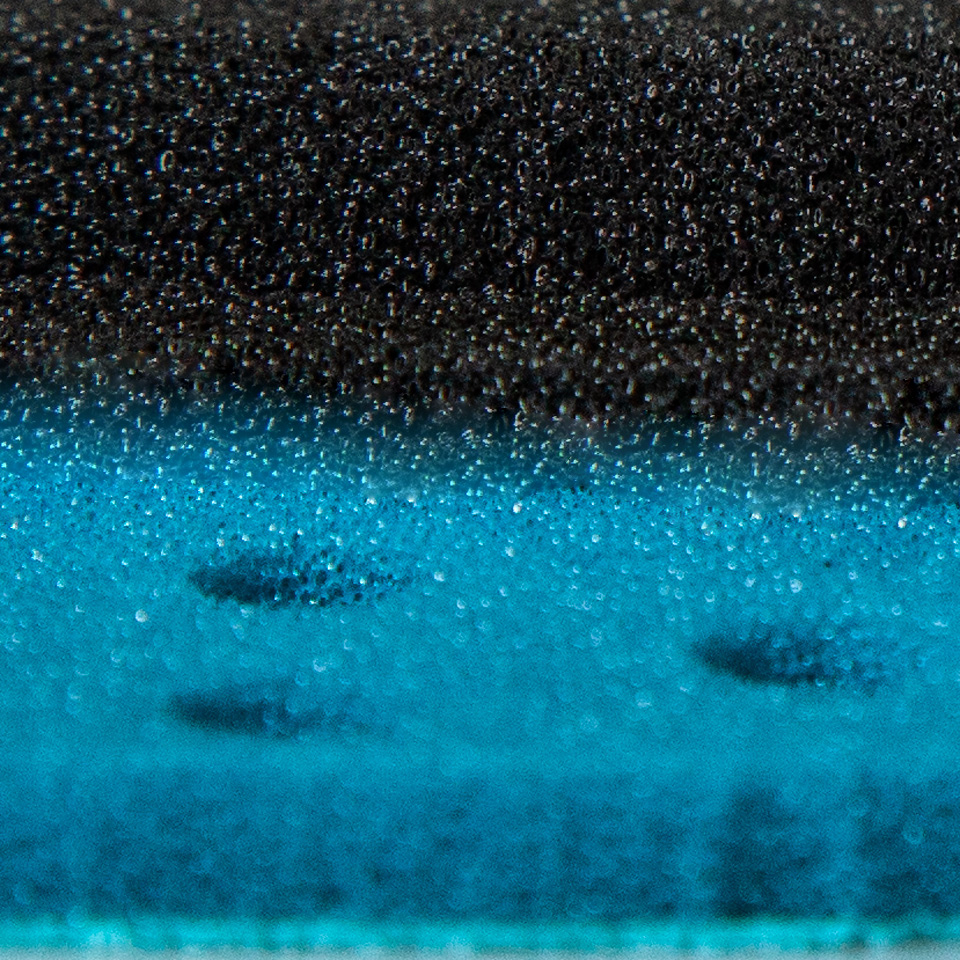

Our research and many years of experience in the sector has led us to develop the SMP3 technology, which is a compound made up of 3 reticulated polyurethane foams of different densities and thicknesses. These are joined by a PUR glue lamination process with a micro - dot texture that allows complete breathability between the layers of the compound.

The triple interface between materials of different densities guarantees the best absorption of vibrations while pedaling and a maximum elastic return of the foams between the saddle and the buttocks in order not to dissipate the effort applied by the cyclist.

This technology is also available in different combinations of materials, called SMP2 and SMP1.

The triple interface between materials of different densities and thicknesses ensures the best absorption of vibrations while pedaling, along with the maximum elastic return of polyurethane foams between the saddle and buttocks so as not to dissipate the effort applied by the rider.

The double interface between materials of different densities and thicknesses provides greater comfort than traditional seat pads due to the absorption of vibrations during pedaling and the excellent elastic return of the polyurethane foams present.

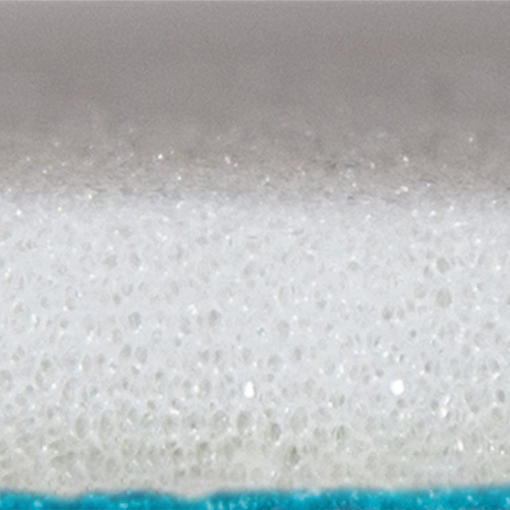

This product range features a construction characterized by a single layer of polyurethane foam, suitable for short rides. Its composition allows the pad to be soft, elastic, and thicker at pressure points.

Together with our partners we have developed a range of fabrics intended to offer the best technical solutions to our customers. Starting from the fundamental characteristics that all materials in the field of cycling pads must have, we have focused on eliminating the possible negative factors that a cyclist faces during the performance: irritation, abrasion and poor breathability. In fact, our fabrics are stretchy and pleasant to the touch thanks to the raising process, include antibacterial treatment and allow a rapid drying when it comes to humidity and moisture. These features optimize the most important aspect that an athlete looks for in the chamois: comfort.

The relentless search for innovative materials allows us to have a range of polyurethane foams at the forefront in terms of technology and efficiency. These are subject to the reticulation treatment, making them completely breathable and elastic unlike standard materials on the market. The various densities and thicknesses in which they are available offer the cyclist extreme comfort for many hours and prolonged over time. The characteristics of these polyurethanes make the pad absorb the various stresses during pedaling and, thanks to the study of a precise stratification, completely satisfy the anatomical needs.

The "SAN MARCO PADS" products are the result of an eco-sustainable idea and working process that considers the protection of the environment a priority. All our raw materials derive from certified suppliers who constantly support us in the development of recycled materials, maintaining the same level of quality. The various factors that put us at the forefront in this field are the use of fabrics with recycled yarn, the reuse of polyurethane foam processing waste and, thanks to new working methods, the poor use of adhesive sprays.

VIA SANT’ANTONIO, 26 - 31030 CASTELLO DI GODEGO (TV)

VIA MARINI, 97 - 31020 SAN ZENONE DEGLI EZZELINI (TV)

IT04085600262

©2024 All Rights Reserved. SANMARCO PADS